|

|

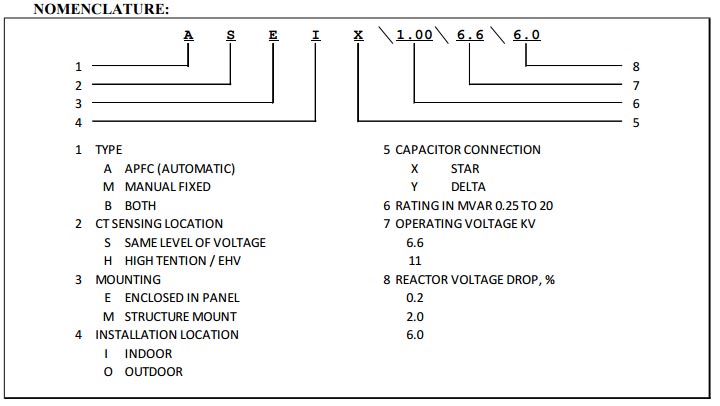

| APPLICATION: CTR Medium and High voltage Reactive power compensation systems are most reliable since all equipment and spares are designed and developed by CTR and manufactured in collaboration with well-known oldest manufacturer of reactor in the country. We undertake complete turnkey projects in the field of MV / HV side Reactive power compensation systems which are widely required in large cement steel textiles plants, large capacity water pumping stations, power generation, transmission utilities and oil refineries in order to maintain Power Factor accurately. As a turnkey package, CTR offers equipment like Capacitors, Current Limiting or Harmonic filter Reactors, Residual Voltage Transformers, (RVT), NCT, Vacuum contactors, CT, PT, LA, HT APFC Control Panels and Monitoring systems, enclosures and required mounting structures. Our team have expertise in turn key projects with support capability from design to successful implementation of the projects including erection and commissioning. Our APFC systems operates in Auto and Manual mode in 2 to 16 stages and full-fill the need of required reactive power in the large capacity switching loads. MV / HV Capacitors are designed for low loss, stable construction oil cooled and are type tested including life endurance test at NABL accredited laboratories. Series Reactors of Magnetically shielded and Air core type are constructed in Copper and Aluminum windings and vacuum dried for very high and reliable performance. SELECTION: Metal Enclosed APFC panels from the voltage range 3.3, 6.6, 11 KV to 33 KV are manufactured in required switching stages through vacuum contactors or vacuum circuit breakers. Outdoor structure mount capacitor and reactors can be controlled through APFC control panels remotely. CTR team can support its customers in order to select and estimate the precise requirement of KVAR ratings, reactors and stages, including power quality studies to resolve existing system operational problems. |

|

| TECHNICAL DATA: Capacitors: 1.1 KV to 40 KV, Single phase / Three phase assembled banks in single stage up to 12 MVAR. Low dielectric losses 0.2 W /KVAR, excellent performance and reliability, high current handling capacity, longer electrochemical life span, environment friendly with high thermal stability. |

|

| Series Reactors: Copper and Aluminum wound with 2% for limiting inrush current, 6, and 7 % for harmonics reduction and provide smooth reactive power. Indoor and outdoor structure / panel mount to be selected as per available space and requirements. | |

| Indoor /Outdoor Installations: Steel rack mounted capacitors and reactors suitable for outdoor duty along with all open execution accessories and protections ranging from 3.3 KV to 132 kV and in KVAR values from 1 to 40 MVAR. In the same way, complete systems can be enclosed in the indoor or outdoor panels / enclosures as per the site conditions. | |

| Benefits: Optimize KVAH closer to the large capacity loads both at utility metering and feeder side. Eliminate power Factor penalties and gain incentives. Savings in maximum Demand Charges, Reduction in current drawn nearer to load helps in lowering the conductor size. Increased life of switchgears due to reduced temperature and I 2R losses. Improved voltage regulation. Reduced space requirement. Easy and lower maintenance cost. | |

| Hybrid HV Compensation Systems: Since nationwide electricity tariffs are being restructured, and all of the utilities are now accepting KVAH based tariffs, CTR has extended arms to offer a complete solution to optimize KVAH to minimum possible by developing MV/HV hybrid systems which consists of regular auto controlled HV banks and additional LT switched capacitor banks OR Dynamic Active Reactive PF correction systems OR NPFC, to micro fine tune the KVAR injection as per the system reactive power requirement trend as recorded during Power Quality studies. | |

| Need to be designed only after the study of load patterns trends of the feeders / substations. During design the Fixed base load + Long duration variation and short duration variation is considered along with their own requirement of reactive power. For Fixed base loads, Fixed compensation with all protections, for long term variable APFC and for short term variation soft switched IPFC are housed together and controlled through single smart APFC Controller which helps to maintain the Power Factor guaranteed above 0.99. Here Soft Switched IPFC helps to reduce the Heavy Bank switching Operations up to 90 % due to its dynamic smart intelligence and helps to reduce switching transients, enhance life of overall system. Further to this NPFC and Dynamic Reactive Power Compensators are also coupled together enable to optimize KVAH and maintain KWH and KVAH difference to minimum and the ultimate performance of hybrid systems. | |

|

|

|

|

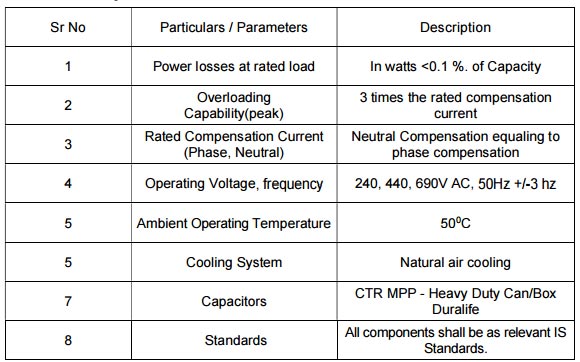

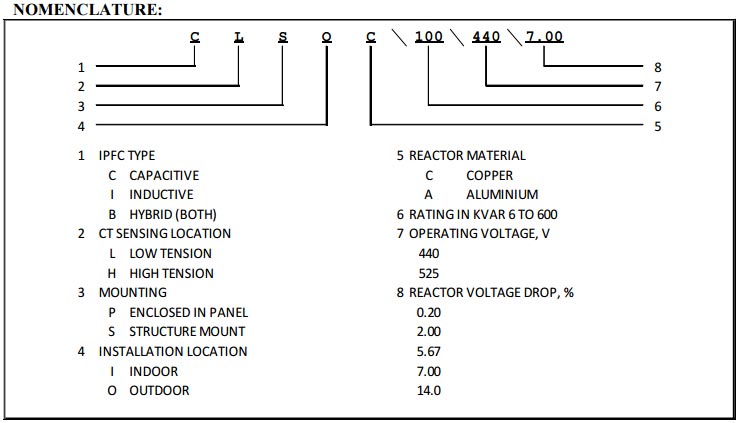

| APPLICATION: Almost all Power Factor correction systems designed by experts and installed by customers are suitable for balanced and partially variable loads consisting majorly of industrial loads. IPFC is designed to correct the power factor of sudden and cyclic switched on and off types of loads including imbalanced loads like Welding (Arc, Seam, CO2, Butt and all others), metal Pressing, Forging, Printing, cranes, magnetic loaders, induction hardening etc. wherever these loads are more than 30% of total. Here Power factor correction is big challenge for experts and are unable to maintain PF above 0.90. The equation is like more is the domination of these type of load, more are the complications in sustaining PF correction. Correcting power factor of such loads, by APFC, will always have leading and lagging KVARH counts more and results in higher KVAH. CTR has developed IPFC (Instantinous Power Factor compensator) which monitors the operation, senses and triggers the capacitor to switch on within 6 milliseconds once the load is on and switches it off immediately once the load is off again within next 6 milliseconds. The system is built in such a way that frequent on and off of capacitors doesn’t affect the life and equipment performs for longer life. SELECTION: It is recommended to select correct rating with the electrical supply system where the Power Factor problems are already identified and solution is designed. It is also important to know the overall effect of the problem to be resolved by use of right rating of IPFC. |

|

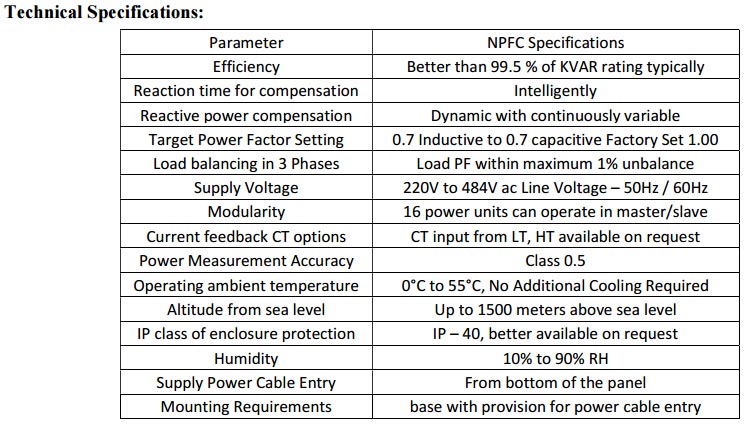

| TECHNICAL DATA: IPFC is a PLC controlled single CT sensing device for load and handles imbalance and Instantaneous variations in the load using high speed Soft Switching arrangement and has capacity to withstand the stress occurring during high speed switching and thus intend to offer better equipment reliability. IPFC design is very compact so as to be accommodated in a small wall mount space near loads and energy efficient to have minimum power loss. IPFC responds for load variation very quickly several times and have capacity to compensate leading power through Neutral wherever there is imbalances in the system. System is capable to maintain the power factor above 0.95 to 0.99 consistently, and is also capable to minimize the difference between KWH and KVAH to minimum at ~1 %. Technical Specifications: Low losses, commercial viability and no maintenance cost are the major advantages of IPFC over other imbalanced load PF correction options available like Active Filter, where in all other equipment cycle operational losses are in multiples of their cost. |

|

|

|

|

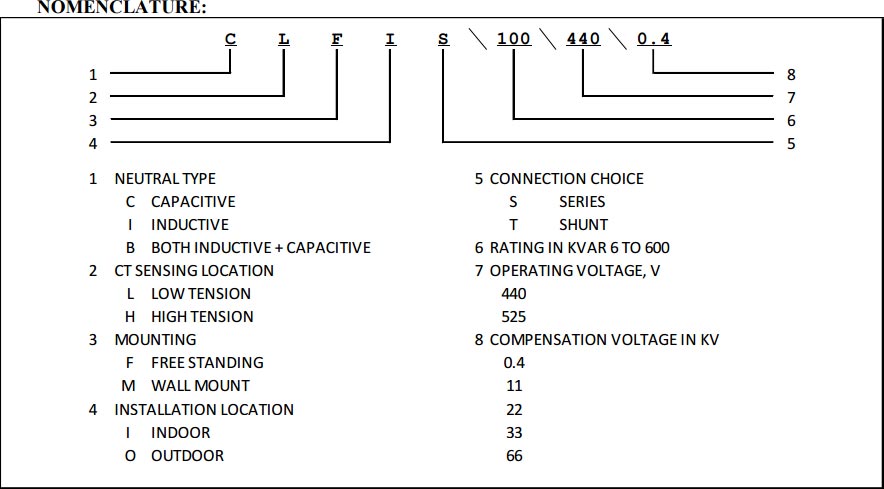

| APPLICATION: CTR NPFC (Neutral PF Compensator) maintains Power Factor 0.999 in the most imbalanced and critical load setup like hotels, hospitals, commercial buildings, offices, educational institutes, large residential buildings, industries, and all installations where PF and Optimize KVAH is a challenge. Perfect solution to eliminate Power Factor penalty and qualify for Power Factor incentive in electricity billing where PF incentive based tariff is in force. Reduction in the KVAH consumption almost equal to KWH, hence direct savings in Electricity Bills. Almost all Power Factor correction systems designed and installed are suitable for balanced loads, consisting majorly of industries. There are no systems designed to correct the power factor of imbalanced loads like lightings, air conditioners, single phase motors, electronics control systems normally where these loads are dominantly higher than 10 %. Here Power factor correction is big challenge to experts and not able to maintain it above 0.96. The equation is like more the domination of imbalanced load, more complications in PF correction. NPFC is a perfect solution to be installed for low rating unit and it works as a top up and master PF brain with the existing APFC / RTPFC and fine tunes the Power Factor at micro level. SELECTION:It is recommended to select correct rating with the electrical supply system where the Power Factor problems are already identified and solution is designed. It is also important to know the overall effect of the problem to be resolved by use of right rating of NPFC. TECHNICAL DATA: NPFC continuously monitors and corrects Power factor by injecting required leading or lagging reactive power through Neutral path in order to maintain the target power factor above 0.999. Unity Power factor is desirable for better economic and technical operation of the system. Usually PF correction means to generate reactive power as close as possible to the load which it requires rather than generate it at a distance and transmit it to the load, which otherwise results not only in large conductor size but also in increased losses. NPFC models available with AC continuous current in three phases and Neutral from 6 Amp to 600Amp and are available in several standard ratings: 6, 9, 12, 15, 21, 27, 36, 45, 60, 75, 90, 120, 150, 180, 225, 270. 300, 400, 500, 600 KVAR. NPFC modules for Inductive, capacitive and hybrid power factor available on request. |

|

|

© 2020 J & S Power Solutions - All Rights Reserved

Powered by G2 Media